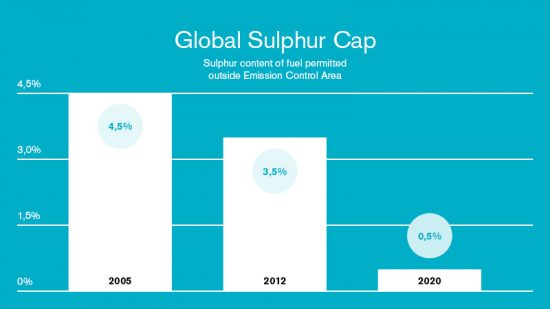

IMO Sulphur Cap 2020 is drawing ever closer; and it is already apparent that transition from 3.5% sulphur content to 0.5% will not be a plain sailing all over the world and is definitely going to add some job to seafarers. However, it is imminent now; and Edmund Hughes, Head of Air Pollution and Energy Efficiency at IMO, expects that 96% of ships, mostly large deep-sea vessels, will be ready to comply with regulations right away (from the 1st of January 2020).

Some shipowners install exhaust scrubbers and are going to carry on with HFO; some will switch to Low Sulphur Fuel Oil to comply. There is also the third way. We have prepared an overview of alternative ship fuels that are considered to be a viable substitute of conventional heavy fuel oil. They produce little or no SOx and allow a considerable reduction of other Greenhouse gases (GHG) emission.

LNG – fueled Vessels

Scrubbers lead in the IMO Sulphur 2020 Cap technological preparation race; over 3 023 ships are furnished with exhaust scrubbers or placed an order for them by October 2019. Meanwhile, Liquefied natural gas top the bill in the alternative fuels league. As of February 2019 there were 143 LNG-powered ships in operation and 135 more were under construction.

Vessel engines require comparatively few modifications to use LNG as a fuel. Nonetheless, there are several apparent advantages and disadvantages of LNG propulsion:

LNG Fuel’s Pros:

- Liquefied natural gas is the cleanest fuel as it produces the lowest amount of GHG (Greenhouse gases).

- LNG has been used as a vessel fuel since early 2000s, so the technology is quite developed and there is a variety of providers in the market. Competition facilitates price reduction as well.

- Incidentally, the cost of LNG fuel is compatible with the cost of conventional oil fuel. Liquefied natural gas can’t compete with HFO yet due to logistic and other expenses, but unlike other alternative fuels LNG will become a fully-fledged substitute to oil in the nearest future. Experts estimate that LNG fuel proportion in the bulk of vessel fuel will reach 23% by 2050 (it is about 0.3% at the moment).

- Piston engines, gas turbines and supplies for them as well as tanks and piping are available in the market.

LNG Fuel’s Cons:

- LNG can boast a higher energy density than HFO, but its volumetric density doesn’t exceed 43% of HFO. Therefore, fuel tanks occupy 3 to 4 times more space compared to vessels powered by oil fuel.

- Bunkering issues. Some general reluctance to introduce LNG propulsion into the shipping industry was connected with logistic difficulties. LNG fuel still can be found in the limited number of ports around the globe which doesn’t suit the majority of players. Vessels often have long routes and need fuel to be available at the next random port, so companies often “wait and see”.

Methanol is another Promising Ship Fuel

Waterfront Shipping has recently received two beautiful dual-fueled methanol carries. 49 000 DWT Mari Couva and Mari Kokako will run on diesel fuel as well methanol testing its capabilities as a marine fuel.

Actually, CH3OH (methanol) takes the second position after LNG in a promising alternative fuels’ rating. There are certain advantages of this gas which make it more convenient to use on vessels:

- Methanol is liquid between –93°C to +65°C and at atmospheric pressure which eliminates the need of complicated cryogenic containment systems’ installation onboard (the cost of methanol system is about 1/3 of the LNG system).

- It can be produced from natural gas, coal and renewable sources. There are technologies of methanol production from CO2 exhaust fumes directly which appears the most promising in the light of COx emission reduction.

- NOx emissions depend on the type of engine used. There will be 30% reduction in case of 2-stroke-diesel engine (compared to HFO) whilst with four-stroke Otto-cycle engine an emission will be reduced by 60%.

Ammonia as Marine Fuel

Dutch C-Job Naval Architects have recently come up with a concept of ammonia carrier using its own cargo as a fuel. Their research has demonstrated that ammonia is a viable option of alternative fuel in case certain safety measures are taken into account. The main findings of the study include:

- Solid Oxide Fuel Cells are the most efficient power generation option for ammonia fuel, but there are some practical issues (power density, load response) as well high cost of the system that prevent it conversion from a concept into a working model.

- Ammonia fuel doesn’t contain any carbon element; therefore it produces no COx, while NOx emissions are kept on acceptable level, so it is an efficient choice in a view of environmental protection.

- Safe ammonia handling on vessels not built to carry NH3 cargo will require installation of advanced and expensive protective equipment (detectors, shut-off valves to isolate leakages, double-walled piping, etc.)

- Ammonia fuel is free from bunkering dilemma as it is produced all over the world and already transported through the majority of ports.

Hydrogen Powered Ships

H2 is one more curious option of an alternative ship fuel that is considered at the moment. For the use at ships hydrogen is either liquefied (cryogenic liquid has a temperature of -240 Co), stored in a compressed tanks or chemically bound.

Nowadays H2 is produced from natural gas or by the electrolysis. It is possible to conduct the latter at solar and wind power plants simultaneously with electricity production. When produced from renewable energy, hydrogen is one of the cleanest fuels with zero COx emissions. Moreover, marine fuel cells prove to be the most efficient power generator for H2. We described Hydrogen fuel cells in our Shipping 2030: New Technologies in Maritime Industry article before. Both hydrogen and marine cells production cycles are available in the market, but they still remain rather incompatible by price with conventional propulsion.

Meanwhile, Port of Antwerp has ordered “Hydrotug”, the first tug powered by H2. They have found compromise, so it uses the powers of hydrogen and combustion engine. The tug is ultra-low-emission and combines dual-fuel technology and sophisticated particle filter.

The Hydrotug will be built by Compagnie Maritime Belge (CMB) in two years.

Biofuel

Have you ever considered an idea biodiesel or biogas powering a vessel? Nautical engineers in Norway and the Netherlands develop concepts that use biofuel made of hydrotreated vegetable oil, fatty acid methyl ester (FAME) or liquefied biogas. These are mainly passenger vessels, ferries, offshore support vessels and specialized ships.

The main component of biofuel is methane, so its behavior is very similar to LNG or methanol fuels. However, its production proves to be more expensive at present.

Scientists also anticipate certain bunkering problems. Today biofuel is available in certain ports of Norway, the Netherlands, USA and Australia only. Therefore, these projects are developed locally, but biofuel is already included in the DNV GL’s Assessment of Alternative Fuels, studied and taken into account as a real option of alternative fuel for ships of the future.